Overview

From the 40G connectors of the 2010s, to the 400G networks of today, passive Direct Attach Copper (DAC) cables remain a cornerstone of the data center. Their low cost, (lack of) power consumption, and simple implementation keep DACs relevant even as the industry shifts its focus to 800G and beyond. However, as bandwidth increases the distance that DACs can sustain a signal becomes shorter and shorter. DACs are still perfectly serviceably at 800G, but with a range of up to 2 meters.

Active Optical Cables (AOCs) – already an equally essential component for transferring clear signals over great distances – are a poor replacement for passive copper. Their high power consumption – and high cost – make them ill-suited for short-to-medium range transmissions.

The industry has responded to this emerging niche with the development of active copper cables. Unlike their passive counterparts, active copper cables have circuitry at either end that amplifies the signals passing through them, giving them a longer effective range, and lower profile, than DACs. At short to medium range, these new copper solutions also vastly outstrip AOCs in terms of power consumption and cost.

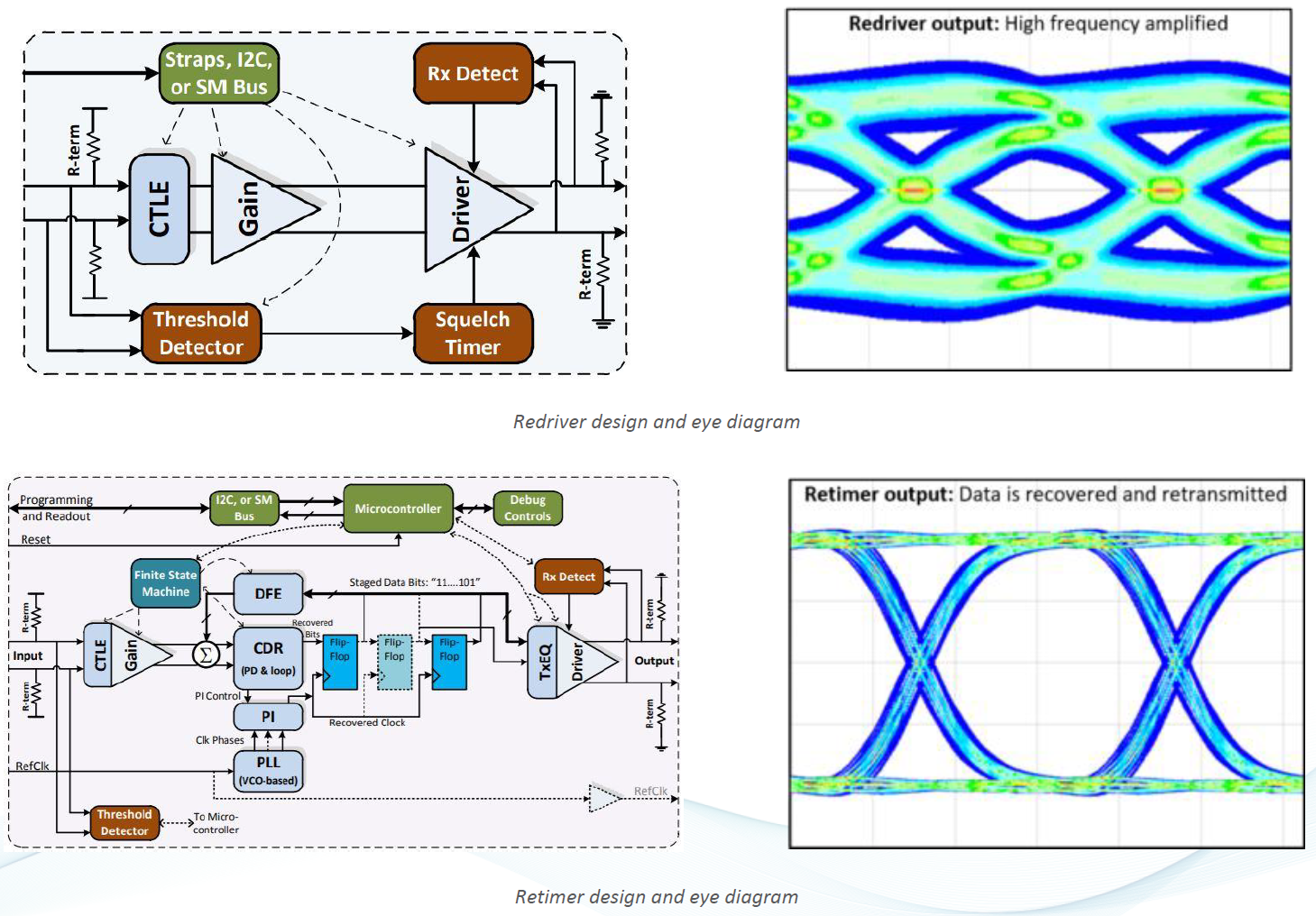

There are currently two types of active copper cables on the market, each of which tackles signal degradation differently. Active Copper Cables (ACCs) use a redriver system, performing continuous time linear equalization on the Rx side to increase signal gain. Active Electrical Cables (AECs) are newer and retimer based. These cables not only equalize and amplify the signal on both the Tx and Rx side, they retime it – regenerating the signal at the Rx side.

Solutions

To enable companies looking to adopt these new technologies, MultiLane has joined the HiWire consortium and offers two distinct solutions for both AEC and ACC testing, as detailed below.

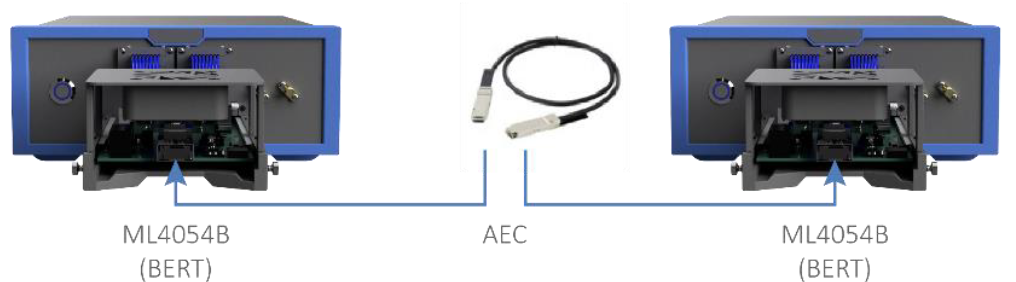

AEC Testers

MutiLane has devised this specific solution for AECs, with parameters put forward by HiWire. Using our specialized instruments, MultiLane tests cables for CMIS validation, linkup capabilities, and realhardware pre- and post-FEC measurements. This solution can be automated for AECs and generates a pass/fail report, making it ideal for incoming inspection, RMA, supplier validation and production testing. MultiLane can also use the same setup for ACCs and AOCs. The DUT is connected to two MultiLane BERTs, with the ML4054B as the default instrument for 400G cables.

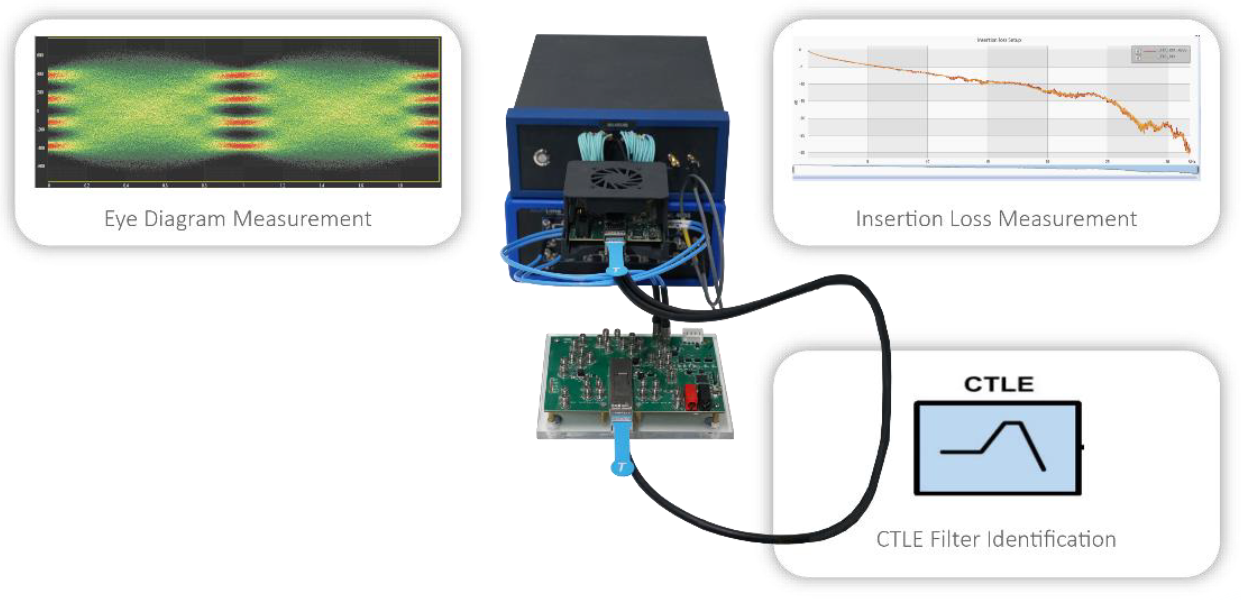

ACC Parametric Cable Testing

As standardized specifications for ACC testing have yet to be established, MultiLane has based this solution on the most common testing parameters being used in the field today: frequency and time domain measurements including eye diagram optimization, insertion loss, and Bit Error Rate. Using our specialized BERTs and DSOs, MultiLane enables manual testing for any combination of the aforementioned metrics, depending on specific customer need. These signal integrity parameters can be used to fine tune the performance of the active cable assembly, as an intricate balance between IC settings and cable parameters.