With the rapid development of artificial intelligence, big data and cloud computing, data centers are increasingly demanding high-speed optical communication modules. Low-power optical(LPO)modules, as an emerging technology,are gradually becoming a popular choice in the fields of data centers and high-speed communications due to their advantages of low power consumption,low cost,and low latency. However, testing LPO optical modules faces many challenges,especially in large-scale production environments. This article will explore the technical challenges of LPO optical module production testing,solutions,and future development trends.

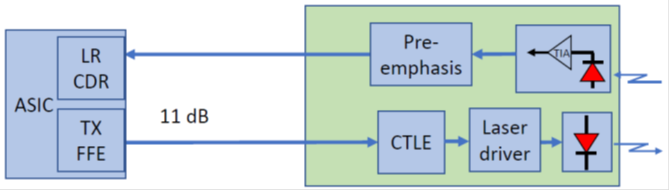

LPO optical modules adopt linear direct-drive technology, eliminating the digital signal processing(DSP) and clock data recovery(CDR)chips found in traditional optical modules. They only retain high-linearity driver chips and transimpedance amplifiers(TIAs)and integrate continuous-time linear equalization(CTLE)and equalization(EQ)functions. This design significantly reduces the power consumption and cost of optical modules. For example,an 800G multimode optical module using linear drive technology has a power consumption of less than 4W, compared to the traditional DSP-based solution with a power consumption of over 13W, resulting in a reduction of about 70%.

In addition,LPO optical modules have the advantage of low latency.By removing the DSP chip,the system reduces signal restoration time,achieving picosecond-level latency.However,the transmission distance of LPO optical modules is relatively short,mainly suitable for short-distance connections within data centers,such as connections between servers and switches or between racks.

Despite the many advantages of LPO optical modules,their testing faces a series of technical challenges:

(1)Incomplete Standardization

The standardization of LPO optical modules is still in its early stages,and the test specifications have not yet been fully determined.This makes the selection of test equipment and the design of test processes complex.Test results from different manufacturers may vary,affecting the interoperability of LPO optical modules.

(2)Limitations of Traditional BERT

Traditional bit error rate testers(BERT)are mainly used for testing optical modules based on DSP.Their transmit(TX)and receive(RX)performance cannot meet the requirements of LPO optical modules.In actual testing,there is a significant deviation between the test results of traditional BERT and the performance of LPO optical modules in real switch applications.

(3)Increased System Signal Integrity Requirements

Since LPO optical modules eliminate the DSP chip,the host-end ASIC needs to have stronger data processing capabilities to compensate for the missing digital signal processing functions in the optical module.In addition,LPO optical modules are more sensitive to noise and jitter in the host-end signal.Differences in signal integrity among different host ports may lead to unstable test results.

(4)Complexity of Large-Scale Production Testing

Although the TH5 Ethernet switch performs well in testing LPO optical modules,it suffers from supply shortages,complex use and management,unsuitability for large-scale production testing,and high total cost of ownership(TCO).Therefore,developing a high-cost-performance and large-scale production-friendly test solution is an urgent need.

In response to the above challenges,Shenzhen Tangling Technology Co.,Ltd.has introduced the LPO BERT test platform for LPO optical module manufacturers,offering an innovative solution for production testing of LPO optical modules.This test platform integrates powerful TX and RX compensation capabilities,supporting up to 26 FFE RX compensation and 6 taps FIR TX compensation,which can effectively compensate for insertion losses of up to 40dB.It can also integrate two 800G optical ports(OSFP/QSFP-DD)and one 800G electrical port(MXP cable),allowing for simultaneous testing of three modules,significantly improving testing efficiency.The platform supports eight single-channel,four(2-in-1)channel,and two(4-in-1)channel FEC layout modes to meet different customer FEC requirements.

RF cable+MCB connection mode OSFP/QDD slot mode

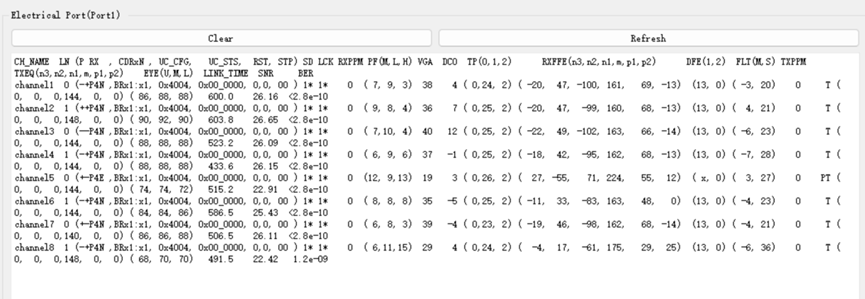

Link training and diagnostic functions are a major feature of this device,which can automatically establish links and find suitable bit error rate(BER)test points.The LPO BERT test platform also provides diagnostic functions,including output of RX parameters such as RX FFE,DFE,eye height(U,M,L),and SNR,supports frequency offset insertion(±300ppm),and can save test logs and custom BERT configurations.Diagnostic parameters can be consistent with those of Ethernet switches.

RX Diagnostic Parameters

In actual testing,the test results of the LPO BERT test platform are very close to those of the TH5 Ethernet switch.For example,when testing LPO optical modules on both the TH5 switch and the LPO BERT test platform,the measured bit error rate(BER)results are almost identical.This indicates that it can provide test performance comparable to the TH5 Ethernet switch while solving the limitations of Ethernet switches in terms of supply,management,and cost,meeting the needs of production testing.

As a low-power,low-cost,and low-latency optical communication technology,LPO optical modules are becoming a popular choice in the fields of data centers and high-speed communications.However,their production line testing faces challenges such as incomplete standardization,limitations of traditional BERT,increased system signal integrity requirements,and complexity of large-scale production testing.The LPO BERT test platform provided by Shenzhen Te-lead Technology Co.,Ltd.offers a high-cost-performance,high-performance,and application-oriented solution for production testing of LPO optical modules,safeguarding the use of LPO optical modules by end customers.