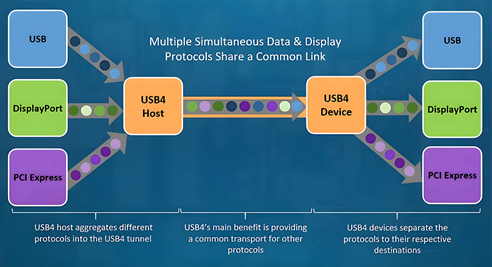

In the consumer electronics field, driven by applications such as high-definition video, VR and AR, the requirements for latency and transmission speed are extremely high. Meanwhile, the previous proliferation of various interface types, such as USB A/B, DP, Type C,HDMI,etc., has forced users to find matching cables or hubs to solve compatibility issues. USB4 is designed to unify these diverse interfaces in an era where multiple types of interfaces coexist. USB4 integrates protocols such as DP, USB, TBT, and PCIe, meaning that a single USB4 Type-C interface can quickly transfer large amounts of data and transmit high-definition video in real time.

With its ability to transmit signals at 20Gbps per lane, USB4 significantly improves video transmission and eliminates issues such as dizziness or discomfort experienced by users during VR gaming due to bandwidth limitations.

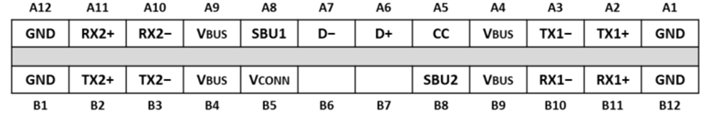

Currently, most USB4 cables on the market are based on USB4 GEN2 and GEN3 standards. Taking GEN3 as an example, with a single-lane transmission rate of 20Gbps, consumer-grade cables cannot use thick copper wires. The maximum transmission distance for passive cables is within 1 meter. For applications like AR and VR, which require longer cables to transmit images, active cables based on Redriver or Retimer, and AOC(Active Optical Cable) types have emerged. Some AOCs may even change pin definitions according to specific requirements. Below is the standard pin definition for a Type-C connector.

From the pin definition,we can see that a standard USB4 cable consists of four pairs of high-speed lines(Tx,Rx)and a pair of USB2.0 lines(D+/D-)for data transmission. These high-speed lines are the core of image and data transmission in USB4 cables. To achieve a transmission rate of 20Gbps per lane, manufacturers must measure the high-speed performance to ensure product quality. Let's take a look at how different types of USB4 cables are measured during the R&D process.

In a passive state, these high-speed transmission lines are typically measured using a Vector Network Analyzer(VNA)to match the S-parameters required by the USB4 specification. This is already a very mature method in the industry.

Active Copper Cables (ACC)based on Redriver chips add power supply and amplify the input signal to extend the transmission distance of passive cables. Due to the analog nature of Redriver chips, the CTLE(Continuous-Time Linear Equalizer)can be adjusted, and the S-parameter specifications can still be used for testing.

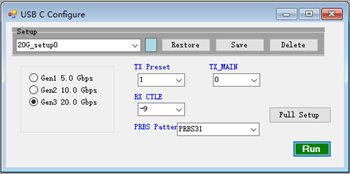

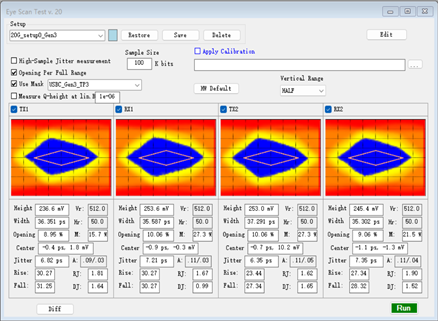

Active Copper Cables(AEC)based on Retimer chips not only add power supply but also perform digital signal reshaping, allowing for longer cable transmission distances compared to ACC. Since Retimer chips are digital, they cannot be measured using a VNA for S-parameters. Instead, time-domain measurements are used. The input signal, which meets the specification requirements, is passed through the AEC, and the eye diagram parameters are measured using an oscilloscope.

Active Optical Cables(AOC),which rely on fiber-optic transmission, have been vigorously promoted in the consumer cable field in recent years. These cables feature excellent resistance to interference and can transmit over very long distances. The core of AOC lies in the electro-optical and opto-electrical conversion in the optical engine. Since the transmission medium of AOC is fiber,VNA is not applicable for measurement. Therefore, the standard compliance signal source plus real-time oscilloscope eye diagram measurement method is still used for product testing.

The above methods are used during the R&D stage. However, production testing aims to improve efficiency and consider cost-effectiveness. For passive or ACC cables, VNA combined with RF switch can be used for measurement, but both VNA and RF switch are expensive. Of course, some instrument manufacturers have introduced low-cost cable testers that can measure USB4,but the measurement functions are similar to those in the USB3.2 era, such as DC resistance, continuity and insertion loss with a precision of 1.5dB. Upgrading to better high-speed characteristic measurements also comes at a significant cost. Moreover, most measurement solutions have significant limitations for active cables, especially for products like AOC.

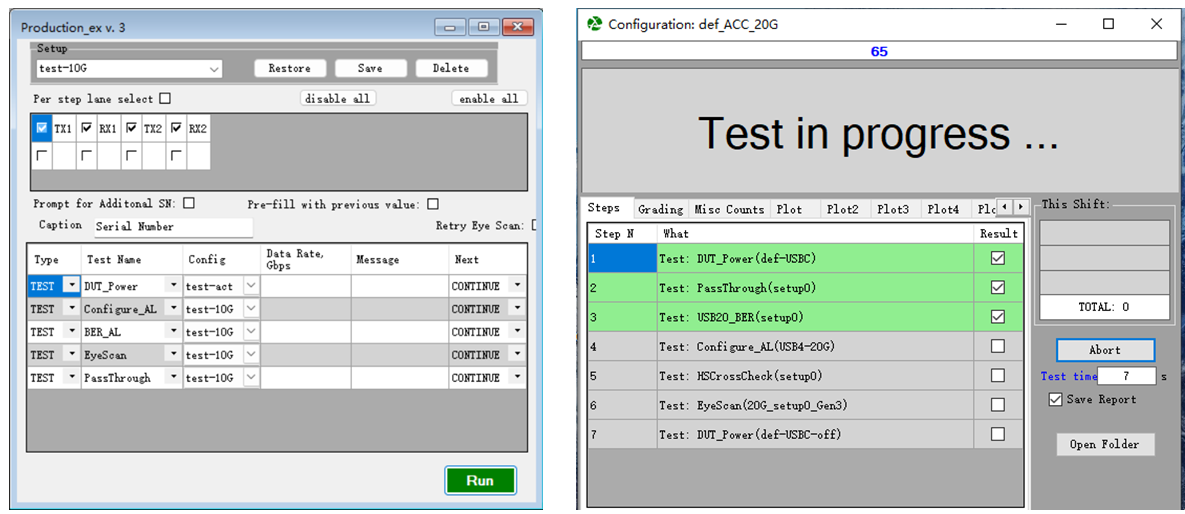

Seeing the limitations of various tests, we are considering whether there is a product that can meet the market's testing needs by providing fast measurement while complying with standards. Together with different cable manufacturers and partners, we have created a new consumer cable tester. This device can measure both passive and active copper cables as well as AOC. It integrates cable continuity measurement, active power consumption measurement, welding misalignment detection, preset and equalization adjustments as specified by the association, and eye diagram template measurement into a single production measurement device. The measurement time for Type-C cables is within 10 seconds or even less.

Tx preset & Rx Equalizer Eye Diagram Template and Measurement

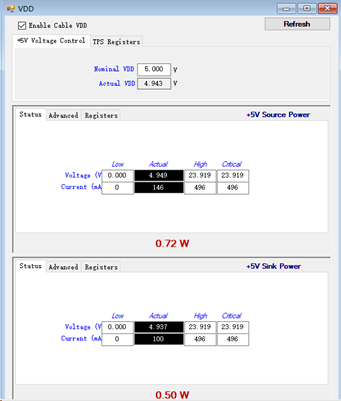

Power consumption measurement

As a production device, it also features shift production statistics, report generation, and database management capabilities, significantly saving customers' time on programming and database management. It is easy to statistically analyze product performance distribution and yield before and after material changes.

Test Sequence and Naming Generation

Future products will add more functions to measure not only Type-C cables but also quickly test Type-C hosts and devices.

For more information on consumer cable measurement, please contact Shenzhen Te-lead Technologies Co., Ltd. directly at sales@te-lead.com.